Operation

Getting Started

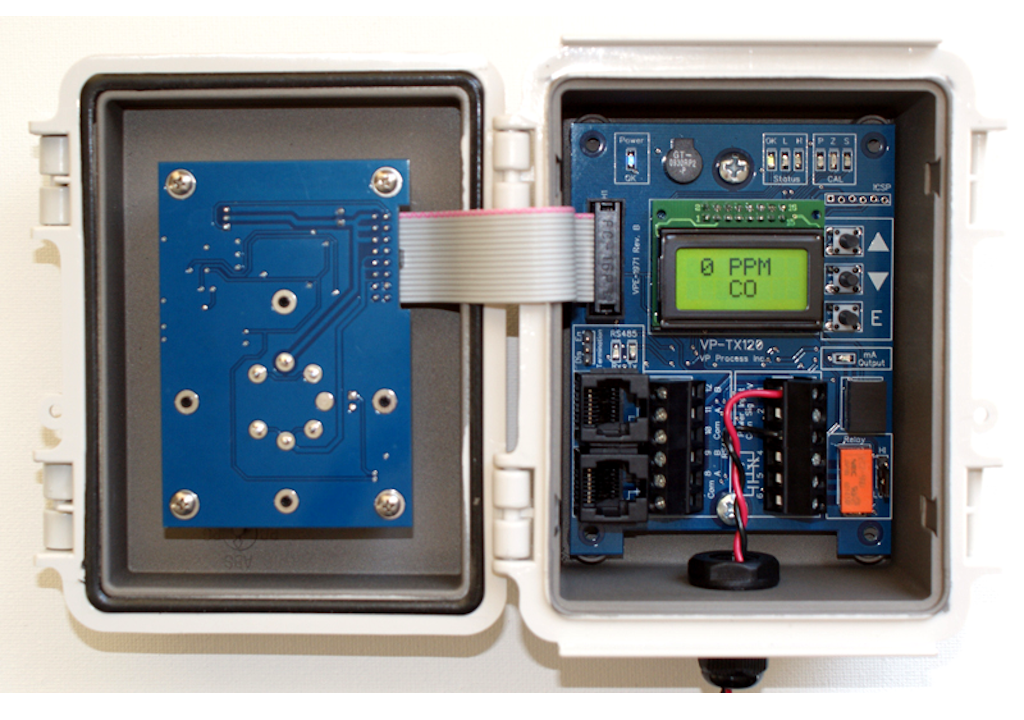

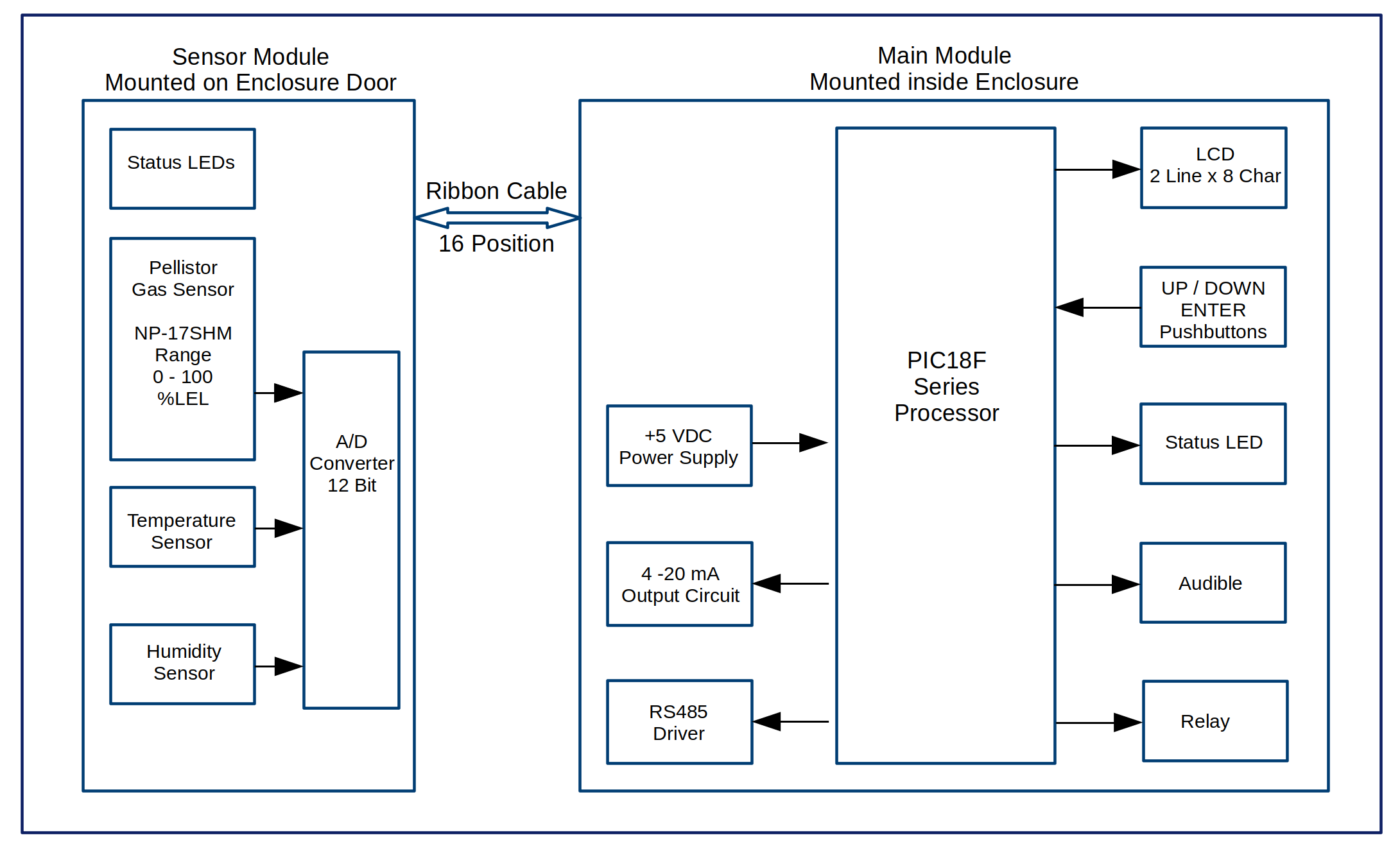

Connect the VP-TX-120-SS Sensor Transmitter as follows:

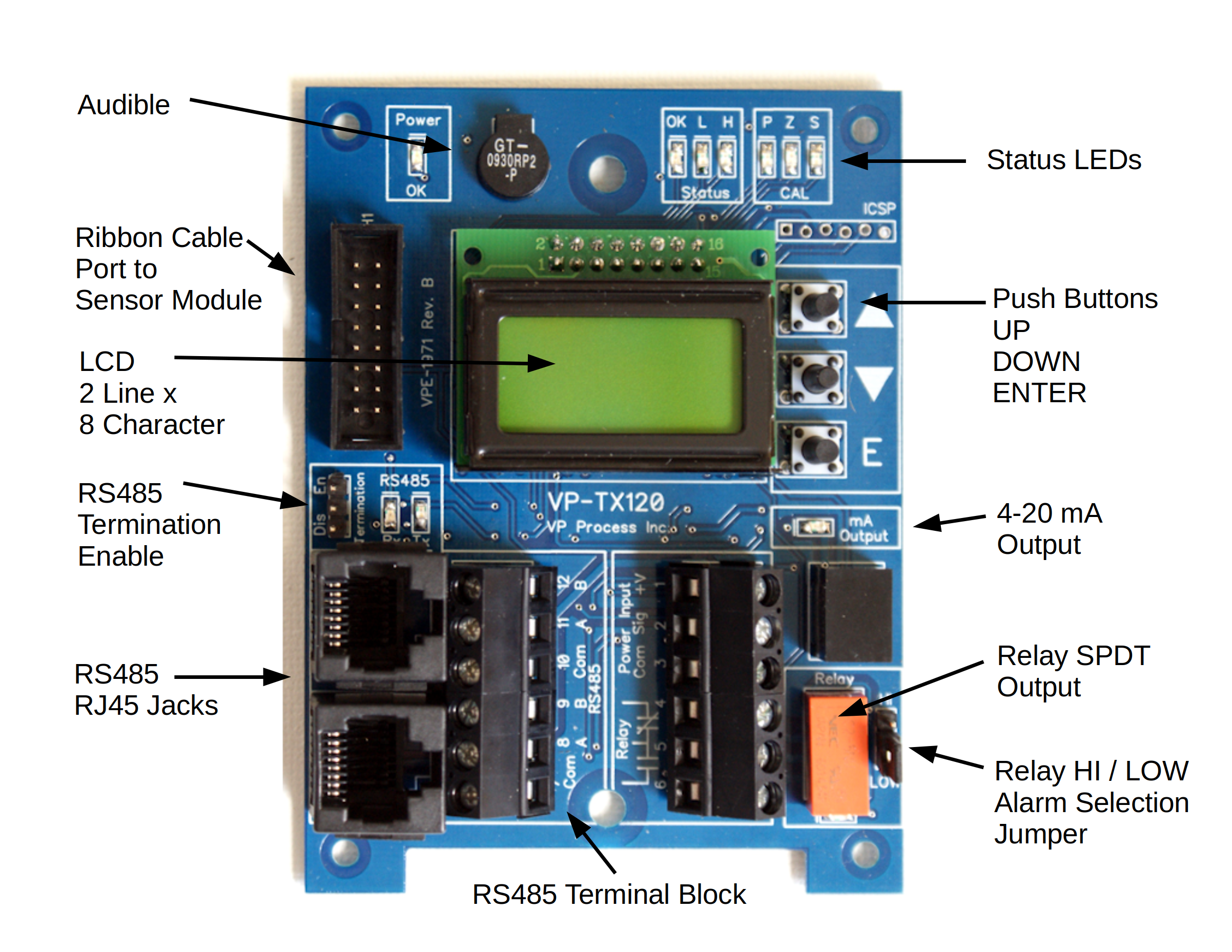

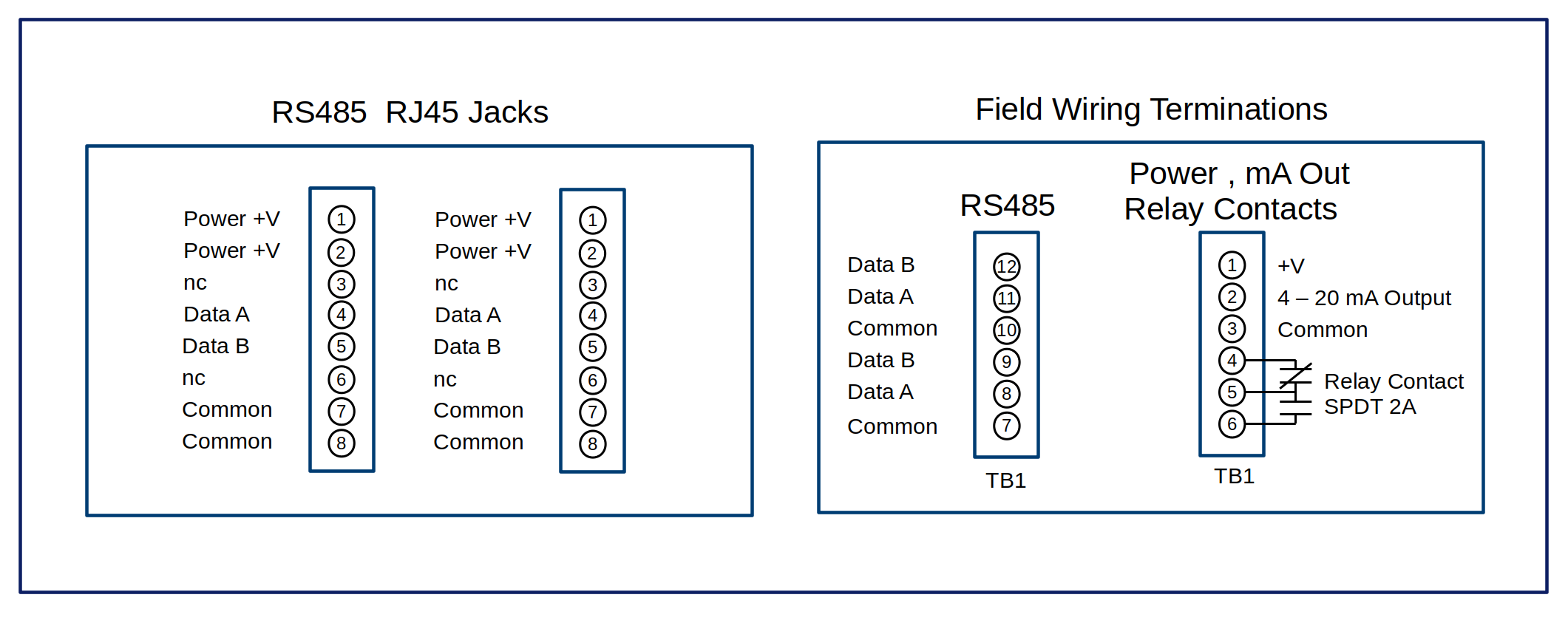

4 - 20 mA Output

+V (24 VDC) to TB1, mA Signal Output to TB 2, Common to TB 3.

RS485 (Modbus RTU Protocol)

Data A to TB 8,11 Data B to TB 9 12, Common to TB 7, 10

NOTE: The Analog Output and RS485 are independent of each other and can be used at the same time.

For RS485 operation, the RJ45 Jack can also be used, the pinout is shown in the block diagram above.

Relay Output

NO TB 5 and 6, NC TB 5 and 4

Power On : There is a 120 Second Power On Timer to allow the sensor to stabilize. If the sensor is cold, the sensor should be

allowed to stabilize for a minimum of 24 hours before performing any calibration. During the 120 Second Power On cycle, the LCD will display:

Start Up Display

Warm Up

In xx

where xx is the number in seconds to full operation

There are 6 Main Display Screens. The different screens are accessed with the UP or DOWN Pushbuttons

Pushbutton Operation : There are three pushbuttons, UP, ENTER and DOWN. The basic operation is UP or DOWN to select the display,

ENTER to start or exit a function.

Back to Top

Normal Operation LCD Screens Examples shown are for a NH3 (Ammonia) Sensor

Screen Number

Screen Display

Description

1. Default Display (after the power on warm up has expired)

0 %LEL

CH4

Default Display, shows the current gas value and units

2. Fault Display

SENSOR

FAULT

If the sensor is disconnected or in fault condition

3. Local Temperature Display

T Local

24.2 C

The temperature sensor is located on the bottom of the PCB ( Near TB 12)

4. Humidity Display

RH

40 %RH

Note: If there is no %RH sensor connected, this display is not shown

5. Software Version Display

TX120-NP

Ver 1.1

Product Model and Software Version

6. Calibration and Programming Menus

Setup

Enter

Programming Entry point, Press ENTER to start

Note: During normal operation or programming operation, if a push button is not activated within 120 seconds, the lcd returns to the default display as shown above in point 1.

Back to Top

Programming and Calibration

Password Entry

Select the Program Entry Screen

Setup

Enter

Press Enter

Select the Password Enter Display

Password

Enter

Press Enter to access the calibration menus

OR Select the Password Exit Display to return to the main displays

Password

Exit

Press Enter to Exit and return to the main displays

Enter the Password

0000

^

The Default Password is 1020 and is hard coded into the device. The password is used to prevent a casual user from accessing the calibration and programming menus

NOTE: To enter a value, each digit is individually programmed by using the UP or DOWN buttons to select a value. Once the desired digit is programmed, press the ENTER Key to select the next digit. After the final digit is programmed, press the ENTER key to accept the programming. (This method is typical for most programming functions.)

Once the correct password is entered and the screen advances to the first program menu (Zero Calibration), the "P" LED will be lit until the user exits the programming manus.

1000

^

0000

^

0020

^

0000

^

Setup, Calibration and Programming Menus

Setup

Menus

Press the UP button for the first Menu Or DOWN button to go in reverse order

Zero Calibration

Zero Calibration

xx

Zero Cal

where xx is the reading in %LEL

NOTE: Before entering the zero calibration, flow 0 gas or fresh air on the sensor to ensure a proper zero gas calibration.

The "Z" LED will be lit during the ZERO calibration.

Press Enter

0

U EN D

where U = UP, EN = ENTER, D = DOWN Push Buttons

Adjust the reading with the UP and DOWN push buttons to read 0. Press the ENTER button to exit and save the the calibraion.

Zero Calibration is Complete

Back to Top

Span Calibration

Span Calibration

xx

Span Cal

where xx is a number representing the current gas reading

NOTE: The user should apply the calibration gas to the sensor for an appropriate time (minimum 2 minutes) to allow the sensor to stabilize to the calibration gas value before entering the span calibration

The "S" LED will be lit during the SPAN calibration.

Press Enter

0

U EN D

where U = UP, EN = ENTER, D = DOWN Push Buttons

Use the UP and DOWN push buttons to make the reading equal to the Span Calibration Gas applied.

Sensor Type

Selecting a New Sensor, Type, Ranges and Setpoints

CH4

Gas Type

where XXX is current Gas Sensor Type

Press Enter

CH4

%LEL

Displays the units of measure for the Gas Type

Sensor Range

Selecting a New Sensor Range

xxx

Range

where XXX is current Gas Sensor Range

Press ENTER to program a new Gas Sensor Range

NOTE: The Analog 4 - 20 mA Output tracks this value

Back to Top

Status LED Set Points

Status LED Low Set Point

xxx

SP Low

where XXX is current Set Point

Press ENTER to program a new Set Point

Status LED Mid Set Point

xxx

SP Mid

where XXX is current Set Point

Press ENTER to program a new Set Point

Status LED High Set Point

xxx

SP High

where XXX is current Set Point

Press ENTER to program a new Set Point

Status LED Set Point Differential

xxx

SP Diff

where XXX is current Set Point

Press ENTER to program a new Set Point

Relay ON / OFF Delays

Set the Relay ON delay in Seconds

xx

On Dely

where XX is current On Delay in Seconds (Default is 1 Second)

Press ENTER to program a new Setting

Set the Relay OFF delay in Seconds

xx

Off Dely

where XX is current Off Delay in Seconds (Default is 1 Second)

Press ENTER to program a new Setting

Audible

Enable Audible ON or OFF

Audible

xx

where XX is current setting On or Off

Press ENTER to program a new Setting

Back to Top

Modbus ID

Program a new MODBUS ID Number

Modbus

ID = 10

The Default Setting is ID = 10

Press ENTER to program a new ID ( 1 thru 253 )

RS485 Baud Rate

Program a new Baud Rate Number

xx

Baud

where XX is current Baud Rate Setting

Press ENTER to program a new Setting ( 9600 OR 19200 Baud)

Calibrate 4 - 20 mA Output

4 mA Calibration

4 mA

Cal

Press ENTER to Calibrate the 4 mA Setting

Update 4 mA Calibration

Cal 4 mA

U EN D

Measure the mA Output

Press the UP or DOWN push buttons to give a 4.00 mA Output

Press ENTER to Exit

20 mA Calibration

20 mA

Cal

Press ENTER to Calibrate the 20 mA Setting

Update 4 mA Calibration

Cal 20 mA

U EN D

Measure the mA Output

Press the UP or DOWN push buttons to give a 20.00 mA Output

Press ENTER to Exit

Manual 4 - 20 mA Output

Test Calibration

Manual

Output

Press ENTER to set a 0 to 20 mA Output

Used for testing purposes. The analog output can be set to a pre-determined value for system testing. Once the Menu is exited, the analog output reverts back to normal operation and tracks the gas value.

Exit Programming and Calibration Menus

Exit

Setup

Exit

Press ENTER to Exit

End of Programming Menus

Back to Top

Temperature Sensor Calibration

There is no calibration needed for the Temperature Sensor. The VP-TX120-CH4 has been programmed with a Steinhart equation for calculating the temperature value based on the Thermistor reading and Thermistor Beta value (B 0/50 = 3380). A 1% Thermistor is used and typically the accuracy is +/- 1 °C over the operating range of -20 to + 60 °C.

Humidity Sensor Calibration

There is no calibration required for the humidity sensor. The VP-TX120-CH4 has been programmed with the transfer function supplied with the Honeywell HIH series sensor. After Temperature compensation, the Humidity sensor is guaranteed to have an accuracy of +/- 3% RH from 5 to 95 % RH range, non-condensing.

Status LED

The Status LED shows the following:

GREEN = OK, RED (Flashing) = Sensor Fault, AMBER = Low Alarm, AMBER (Flashing) = Mid Alarm, RED = High Alarm

Audible

The Audible can be programmed either ON or OFF and is fixed to the HIGH alarm setting. If the Audible is enabled and ON, it can be silenced by pressing any pushbutton.

The Audible is also used as a pushbutton "Click". This feature is always enabled.

Back to Top